Exactly How to Prevent Weld Undercut: Essential Tips for Welders

Understanding the Causes and Solutions for Undercut Welding in Metal Manufacture Procedures

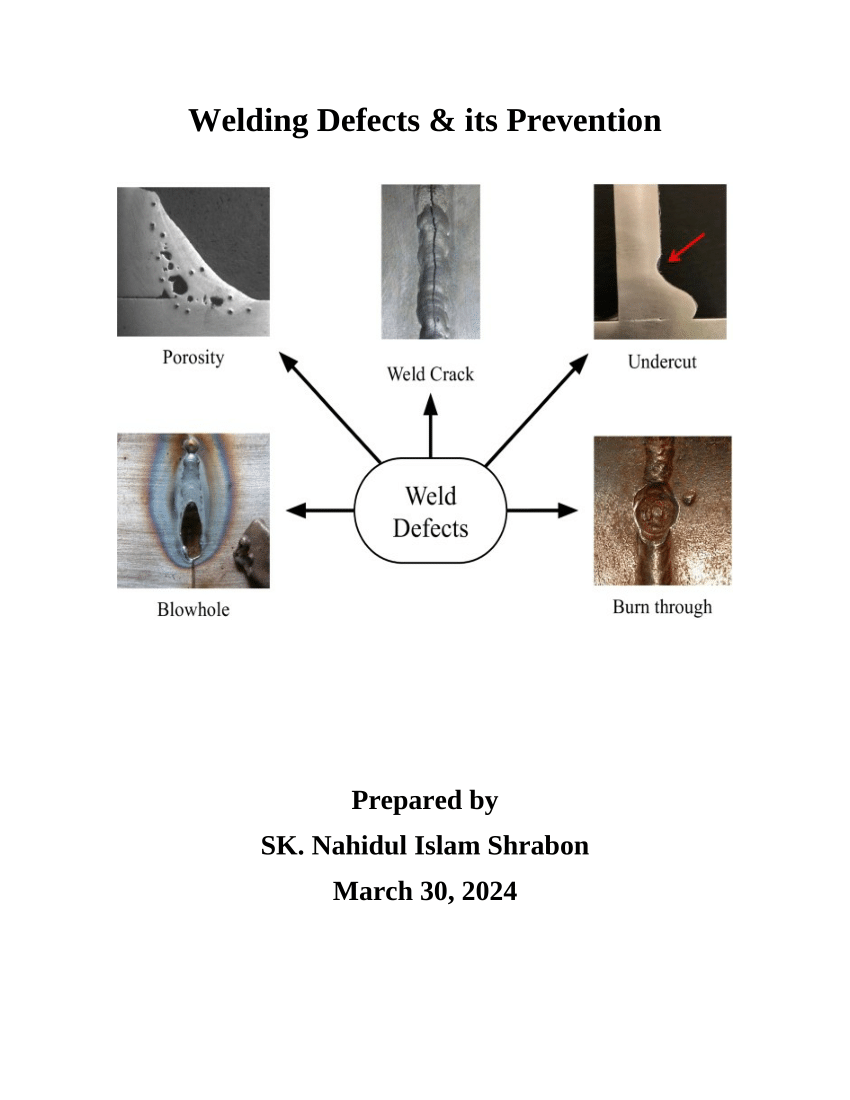

In the world of metal manufacture processes, the occurrence of undercut welding postures a substantial challenge that demands a detailed understanding of its reasons and practical services. The detailed interaction of numerous aspects during welding procedures can result in this unwanted sensation, impacting the architectural honesty and overall quality of the welded joints - Preventing weld undercut. By exploring the origin of undercut welding and checking out effective therapeutic measures, fabricators can elevate the requirement of their handiwork and ensure the manufacturing of flawless steel parts

Usual Reasons For Undercut Welding

Frequently overlooked in steel fabrication, undercut welding happens because of various aspects that require precise focus and proficiency to be efficiently mitigated. One typical reason for undercut welding is excessive warm input. When the warmth input is too expensive, it can result in the melting and subsequent erosion of the base product along the edges of the weld joint, producing a groove or undercut. In addition, incorrect welding techniques, such as utilizing the wrong welding angle or take a trip rate, can also add to undercut development. Poor securing gas insurance coverage is another essential aspect that can cause damaging. Inadequate gas protection fails to secure the weld swimming pool sufficiently, causing oxidation and undercut defects. The selection of welding specifications, such as voltage, present, and cable feed speed, plays a significant role in the incident of undercut welding. Understanding these usual reasons is critical for applying preventative measures and guaranteeing high-quality welds in steel manufacture procedures.

Influence of Incorrect Welding Parameters

Unreliable welding criteria can considerably compromise the honesty and top quality of bonded joints in metal construction processes. The influence of inaccurate welding specifications manifests in different means, leading to structural weak points and flaws in the welded elements. Precise interest to welding criteria is critical to ensure the manufacturing of top notch welds with the wanted mechanical homes and architectural stability.

Effect of Improper Lantern Angle

Inappropriate lantern angle in welding operations can considerably affect the top quality and integrity of the last weld joints in metal construction procedures. Damaging is an usual welding issue where a groove forms along the weld toe, damaging the joint and compromising its architectural honesty.

A torch angle that is also steep can bring about insufficient penetration, insufficient combination, and boosted spatter. On the other hand, a torch angle that is too shallow can cause excessive infiltration, burn-through, and distortion of the base material. Preventing weld check out here undercut. Proper torch angle is crucial for guaranteeing regular weld top quality, toughness, and look

To avoid damaging and various other problems brought on by improper lantern angles, welders have to be educated to preserve content the proper torch angle throughout the welding procedure. Regular tracking and modification of torch angles throughout welding can assist attain sound welds with very little defects.

Duty of Inadequate Welding Methods

One more facet of inadequate welding strategies is inappropriate weld prep work. Insufficient cleaning of the base metals, inaccurate joint style, or inadequate edge prep work can all add to damage welding. Moreover, poor securing gas insurance coverage or utilizing the wrong kind of gas can result in incomplete combination and the formation of undercut issues.

To deal with the role of inadequate welding strategies in steel construction processes, it is important to supply comprehensive training for welders. Correct education on welding parameters, joint prep work, and securing gas option can help avoid undercut welding and guarantee high-quality welds in steel manufacture tasks.

Efficient Solutions for Undercut Welding

Dealing with undercut welding in metal fabrication requires executing efficient remedies to improve weld high quality and architectural integrity. Among the primary solutions to deal with undercut is to change welding parameters such as voltage, present, and take a trip speed to guarantee appropriate warmth input and combination. By fine-tuning these settings, welders can stop extreme melting of the base metal and filler material, lowering the chance of undercut development.

Additionally, correct joint preparation is crucial in protecting against undercut. Making sure clean base steel surface areas totally free of contaminants and using the suitable bevel angle can aid advertise far better weld infiltration and decrease the risk of undercut - Preventing weld undercut. Employing see page appropriate welding techniques, such as oscillating the torch or weaving, can likewise help in distributing warmth uniformly and filling the weld joint sufficiently, minimizing the possibility of undercut issues

Furthermore, picking the proper welding consumables, including electrodes and filler steels, is vital in mitigating undercut. Using materials with proper chemical structures and mechanical residential or commercial properties can add to achieving audio welds with very little undercut. Regular examination and quality control procedures ought to also be carried out to spot and resolve undercut concerns without delay, guaranteeing the total honesty of made steel parts.

Verdict

To conclude, comprehending the causes and remedies for undercut welding in steel fabrication procedures is important for attaining high-grade welds. By attending to usual causes such as wrong welding specifications, incorrect lantern angle, and poor welding strategies, welders can protect against undercutting and guarantee strong, resilient welds. It is important to take note of these factors and implement effective remedies to improve the total welding process and final product top quality.